Cybord's AI-powered RTI solution enhances PCB assembly

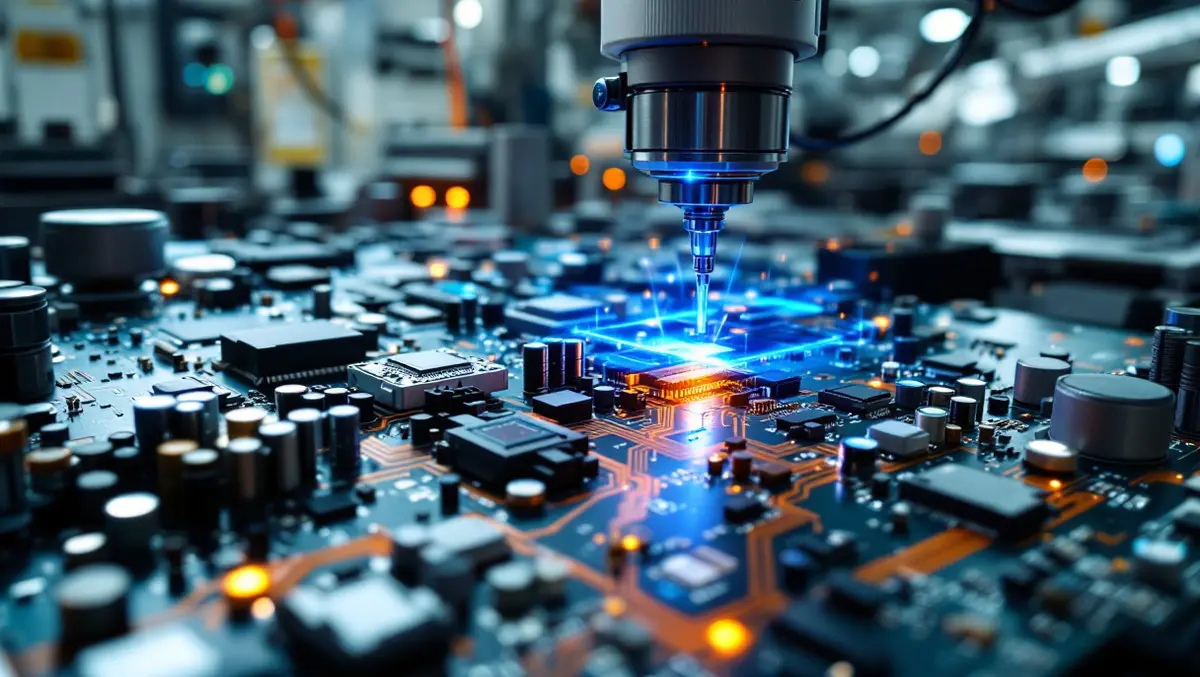

Cybord has launched the Real-Time Interception (RTI) solution to prevent defective components from being assembled onto Printed Circuit Board Assemblies (PCBAs) in real time.

The RTI solution is an advanced visual AI-powered system designed to perform an MRI-like inspection of electronic components on circuit board assembly lines. The launch intends to enhance supply chain efficiency by providing manufacturers with enhanced visibility and transparency, ensuring only defect-free components are integrated.

By identifying and discarding faulty components within milliseconds before placement, Cybord's RTI safeguards product quality, integrity, and compliance, while significantly reducing manufacturing waste and costs. This system, already integrated into Fuji's NXT III placing machines, is expected to be expanded to manufacturing lines worldwide.

The RTI solution empowers manufacturers with an advanced defence mechanism at the component level. By analysing the bottom view of each component in milliseconds, the tool enables manufacturers to mitigate risks proactively and optimise operational efficiency. The solution offers instantaneous detection and rejection of defective components, thereby enhancing the quality control without disrupting production workflows. Additionally, it provides data-driven insights that ensure compliance with IPC standards.

Hirofumi Yoshimi, President of Fuji America Corporation, expressed his excitement about the partnership with Cybord, stating, "From the start of the Fuji America-Cybord partnership, our team was extremely impressed by the capabilities offered by Cybord's RTI and we are thrilled to be the first to integrate this revolutionary solution. Cybord's RTI aligns perfectly with our commitment to enhance quality and product integrity. By integrating the most advanced AI technology into our machines, Fuji ensures that only quality components make it onto boards. In doing so we provide customers with an unprecedented level of reliability and efficiency."

Oshri Cohen, CEO of Cybord, highlighted the importance of component integrity, saying, "Manufacturers can no longer afford to take risks when it comes to product reliability, and it starts at the component level. The lack of visibility into component integrity is costing manufacturers time, money, and customer trust. Cybord's AI-powered RTI solution changes the game. For the first time, manufacturers can see and analyse every single component in real time - and now, they can act. RTI surgically detects and eliminates defected or unauthorised components before they are placed on the PCB, preventing failures before they happen and delivering unmatched reliability, security, and efficiency."

With electronic components serving as the backbone of modern technology, the need for reliable assembly processes is critical. The RTI solution is aimed at reducing the high rates of rework and scrap that have plagued manufacturers due to defective products, as seen in occurrences like automotive recalls or issues in aerospace sectors. Cybord's technology is designed to mitigate these risks effectively.

The Real-Time Interception solution extends Cybord's suite of offerings, which already includes Quality Component Inspection (QCI) and Traceability Component Inspection (TCI). The new technology responds to manufacturers' calls for a preemptive measure against faulty components infiltrating the assembly line. It has garnered significant interest and is currently utilised by major industry players such as Siemens and Flex, alongside Fuji America.

The AI engine of RTI is powered by a database of nearly five billion components, utilising deep learning and AI algorithms to advance electronics manufacturing. Its capacity to prevent defective, damaged, and counterfeit components with 99.9% accuracy is a significant technological step forward. Dr. Eyal Weiss, Cybord CTO and Founder, authored a paper on this technology that was named a Best of Conference winner, reflecting its impact within the technical arena.